Smith and Long Combustion Division is a TSSA-registered company dedicated to gas-fired combustion equipment and services as well as thermal systems in both industrial and commercial applications.

Serving our clients with the highest quality in services and products prevailing performance, safety, reliability, and fuel efficiency.

Smith and Long Combustion Division provides 24/7 emergency response to the following industries:

- Automotive

- Building

- Facility Maintenance

- Food Processing

- Industrial / Commercial Construction

- Packaging

- Utilities

Our services include:

- Bakery ovens

- Paint spray booths

- Paint-curing ovens

- Incineration systems

- Steam and hot water boilers

- Metal melting furnaces

- Metal-hardening furnaces

- Air heat furnaces

- Paper mill equipment

- Packaging equipment

- Special flame effects

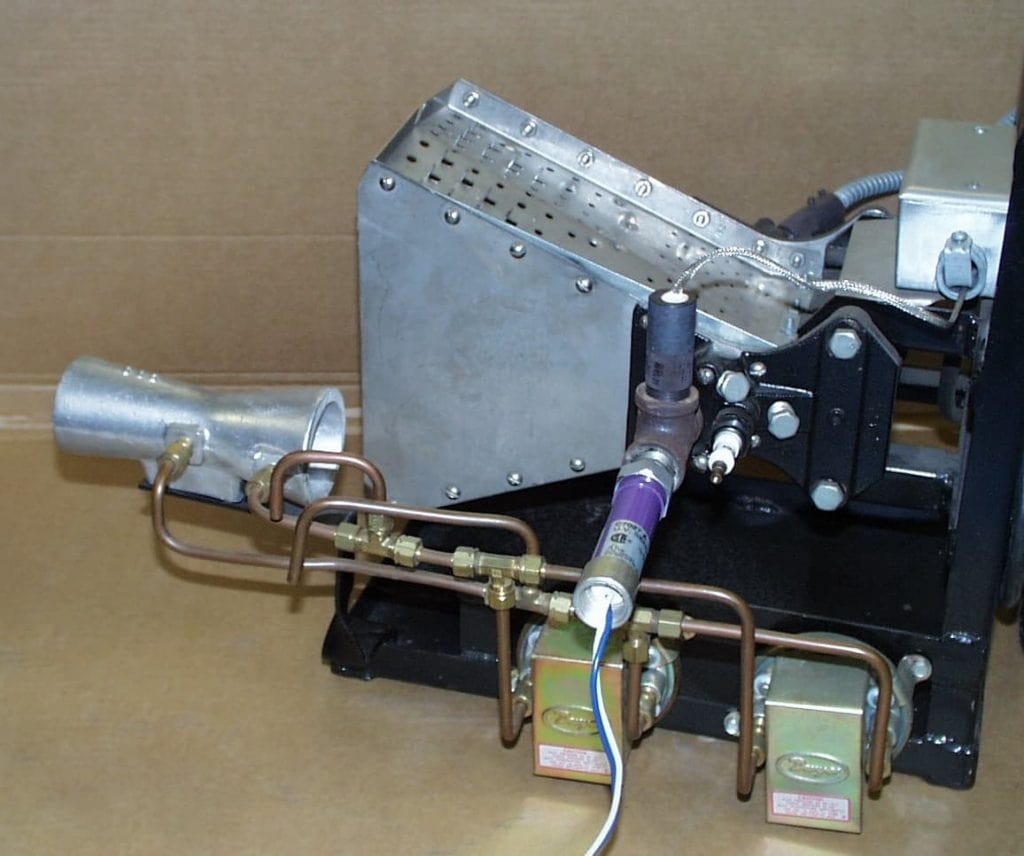

- Valve train stations

- Control panels

- TSSA code & compliance issues

- Gas equipment safety certification

- PLC process automation

- Energy, efficiency, and environmental issues

Do you need

EMERGENCY

COMBUSTION

SERVICE or

MAINTENANCE?

See below.

Smith and Long Combustion Division boasts a comprehensive inventory of piping and combustion system components with installation by a certified technician. As a component supplier to the automotive and OEM industry, we endorse and install products from:

- ASCO Numatics

- Eclipse Combustion, Canada

- Honeywell Limited

- Maxon Corporation

Our process combustion team provides extensive experience in all types of ovens, air houses, and boilers. Smith and Long Combustion Division proudly tenures several specialized products to improve burner safety and reliability and system efficiency:

TD Burner

High turn down and fast response excessive air burner developed for the “hot flash” oven, in which a burst of volatile gasses is released. In conjunction with QR (Quick Response) flow control valve, the burner provides 100 to 1 turn down ratio and fast response of 1 to 2 seconds from low fire to high fire.

Firefox Cascade System (Anti-Foul Purge for Staged Raw Gas Burner)

A system developed to combat the fouling problem on staged raw gas burners in air supply units. The staged burner configuration provides superior air temperature control to 1° to 2° F, however, the gas ports on the idle burner can become fouled by condensation of spent combustion products. In some cases, burner gas ports are fouled in less than six months.

Velocity Monitor

A velocity amplifier designed to boost the low differential pressure typically found across burner profiles in air supply units. The unit is also used to monitor flow in low-velocity supply air and exhaust ducting.

Emitta Ray

This process heating system is designed to focus infrared energy onto products with low mass or where the prime requirement is to heat the surface. The Emitta Ray can be applied to most existing ovens and will allow the oven temperatures to be reduced while maintaining or increasing line speed. Typical applications of this system include automotive paint ovens, car thawing sheds as well as drying and curing operations.

Arctic Pak

Essential to burner reliability in high humidity air streams or cold environments. This compact unit reduces burner faults with the prevention of condensation and frost thus reducing failing flame rods and scanners.

SMITH AND LONG COMBUSTION DIVISION

Emergency Service & Maintenance

Need on-call 24/7 emergency response service?

Our qualified technicians and on-staff Applications Engineer ensure a direct resolution and compliance in accordance with provincial TSSA Fuel Safety regulations.

416-781-6166 x9 and follow the prompts