SAFETY SYSTEMS

Beyond the legal and moral responsibility of every employer to ensure every one of their employees and visitors is safe, all great employers mandate a strong safety culture…because it is the right thing to do.

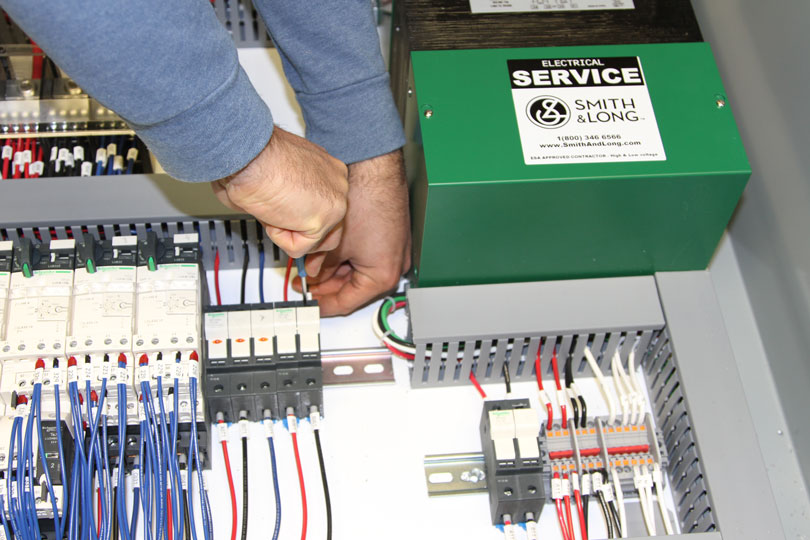

Whether you have new equipment arriving onto your production floor, you have older legacy equipment that has become suspect and needs a review, or an equipment safety issue has become apparent, the professional services of the Smith & Long Integrated Automation & Control Systems Team can work closely with you to review and develop a corrective plan for implementation.

The Safety-First Mandate:

Non-negotiable.

The End Goal: Achieve the balance of operational needs…not as an accommodation of safety and unnecessary risks, but instead design and incorporate innovative safety solutions that do not compromise safety while at the same time enabling the production equipment to do what it was intended to do: Produce.

Pre-Start Health and Safety Reviews (PSR) – A PSR is intended to be a design review prior to the installation of equipment, not an as-installed review, however for various reasons over time as various equipment and or production lines have gone through an evolution without a formal review there is a need to do so. The Smith & Long Integrated Automation & Control Systems Team has the experience and expertise to work with you in performing a PSR that is practical, workable and thorough.

A typical PSR is undertaken before equipment is operated and ideally at the design stage and as such the client must take any measures necessary to bring the construction, addition, installation or modification into compliance before the equipment is operated.

Safety Integrity Level (SIL) – is defined as “a relative level of risk-reduction provided by a safety function, or to specify a target level of risk reduction”. Generally, resultant SIL rating outcomes and the associated requirements have been driven by a formal Hazard and Operability Study (HAZOP) performed in order to identify and evaluate problems that may represent risks to personnel or equipment. The Smith & Long Integrated Automation & Control Systems Team can assist with these reviews through facilitating the upfront assessment process or through the resulting implementation of physical systems and processes to accomplish the required outcomes to align with the various categories of safety compliance.

Safety System Design & Implementation – Throughout any safety assessment and implementation process, it is imperative to engage all stakeholders in a fully collaborative way in order for us to fully understand the fundamentals of the equipment and or production line operation, to the nuances of production, operator roles and responsibilities, quality control mandates and the required minimum throughput. Once that has been performed, the Smith & Long Integrated Automation & Control Systems Team designs, integrates and commissions a combination of safety system relay control panels, annunciation, alarms, guarding, sensing, E-Stops, operator stations, in combination of other available technologies to achieve the mandated level of controls safety redundancy all in a practical, compliant delivery model without added unnecessary complexity

Integrated Automation & Control Systems

Integrated Automation & Control Systems